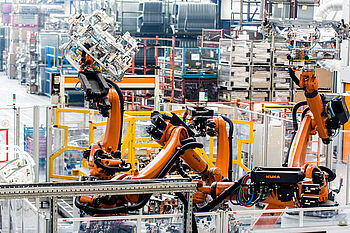

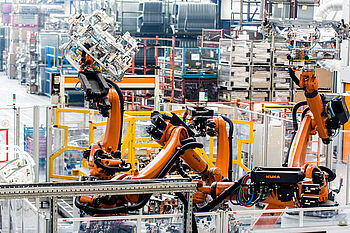

Impressive process know-how, intelligent manufacturing technologies, a clear focus on solutions – LÄPPLE AUTOMOTIVE is a leading provider in the areas of sheet metal part forming and car body assembly for premium vehicles. As a system supplier to the automotive industry, we manufacture pressings and body modules with varying degrees of complexity from steel, aluminium and other lightweight construction materials. We cover the entire sheet metal forming and component manufacturing process – for production models as well as the aftermarket.

You're in safe hands right from the start – LÄPPLE AUTOMOTIVE is a partner on whom you can rely even during the early phases of a project or development. Our expert team will carry out a check as early as the predevelopment phase to determine whether the product can be manufactured to your requirements in principle and will put forward various options. A simulation will be performed to explore methods and feasibility before planning how the solutions are to be implemented at the production level. We will then draw up a detailed method plan and will firm up the details of the system.

We will support you through every step of the process, managing the manufacture of the operating equipment worldwide – a service we offer to all our customers.

We offer structural parts and Class A parts for the latest production models in the form of individual parts or as assemblies. As experts in a variety of materials, we not only process steel and aluminium but also multi-material mixes and advanced lightweight construction materials. Our machinery is geared towards the manufacture of parts for premium and high-volume vehicles in small or large batches. As a result, we can offer top quality at sensible prices.

Our Teublitz storage facility houses more than 13,000 tools for producing spare parts for more than 250 different series. We are a full-range manufacturer of all kinds of spare parts. Thanks to our rapid set-up concepts and optimum cycle times, we can handle the increasing variety of spare parts and you can rely on us to deliver the best possible products and service.

Our in-house relocation and integration team is able to integrate new parts into our existing universal cells with absolute ease. Depending on the age of the parts and the quantities involved, these can be produced by hand or with semi-automated or fully automated systems.

We insist that our products meet stringent quality standards and give our best every day to supply our customers with perfectly precise, high-quality products. This is underwritten by the fact that our employees are constantly gaining new qualifications, as well as our use of intelligent testing techniques. By relying on tactile and optical measuring methods – including both inline and offline measurements – we are able to ensure quality at every stage of production.

You're in safe hands right from the start – LÄPPLE AUTOMOTIVE is a partner on whom you can rely even during the early phases of a project or development. Our expert team will carry out a check as early as the predevelopment phase to determine whether the product can be manufactured to your requirements in principle and will put forward various options. A simulation will be performed to explore methods and feasibility before planning how the solutions are to be implemented at the production level. We will then draw up a detailed method plan and will firm up the details of the system.

We will support you through every step of the process, managing the manufacture of the operating equipment worldwide – a service we offer to all our customers.

We offer structural parts and Class A parts for the latest production models in the form of individual parts or as assemblies. As experts in a variety of materials, we not only process steel and aluminium but also multi-material mixes and advanced lightweight construction materials. Our machinery is geared towards the manufacture of parts for premium and high-volume vehicles in small or large batches. As a result, we can offer top quality at sensible prices.

Our Teublitz storage facility houses more than 13,000 tools for producing spare parts for more than 250 different series. We are a full-range manufacturer of all kinds of spare parts. Thanks to our rapid set-up concepts and optimum cycle times, we can handle the increasing variety of spare parts and you can rely on us to deliver the best possible products and service.

Our in-house relocation and integration team is able to integrate new parts into our existing universal cells with absolute ease. Depending on the age of the parts and the quantities involved, these can be produced by hand or with semi-automated or fully automated systems.

We insist that our products meet stringent quality standards and give our best every day to supply our customers with perfectly precise, high-quality products. This is underwritten by the fact that our employees are constantly gaining new qualifications, as well as our use of intelligent testing techniques. By relying on tactile and optical measuring methods – including both inline and offline measurements – we are able to ensure quality at every stage of production.

In a market environment shaped by crises and planning uncertainties, the LÄPPLE Group maintained its…

The two LÄPPLE AUTOMOTIVE sites in Heilbronn and Teublitz are supporting the current Ukraine-Russia…

The LÄPPLE Group is parting ways with its FIBRO Rotary Tables division: The previous business unit manager Dr. Heiko Asum is taking over the division as part of a management buy-out. The new FIBRO Rundtische GmbH will start operations on January 1, 2024.