SPECIALIST FOR ORIGINAL SPARE PARTS

AFTERMARKET

Our Teublitz storage facility houses more than 13,000 tools for producing spare parts for more than 250 different series. We are a full-range manufacturer of all kinds of spare parts. Thanks to our rapid set-up concepts and optimum cycle times, we can handle the increasing variety of spare parts and you can rely on us to deliver the best possible products and service.

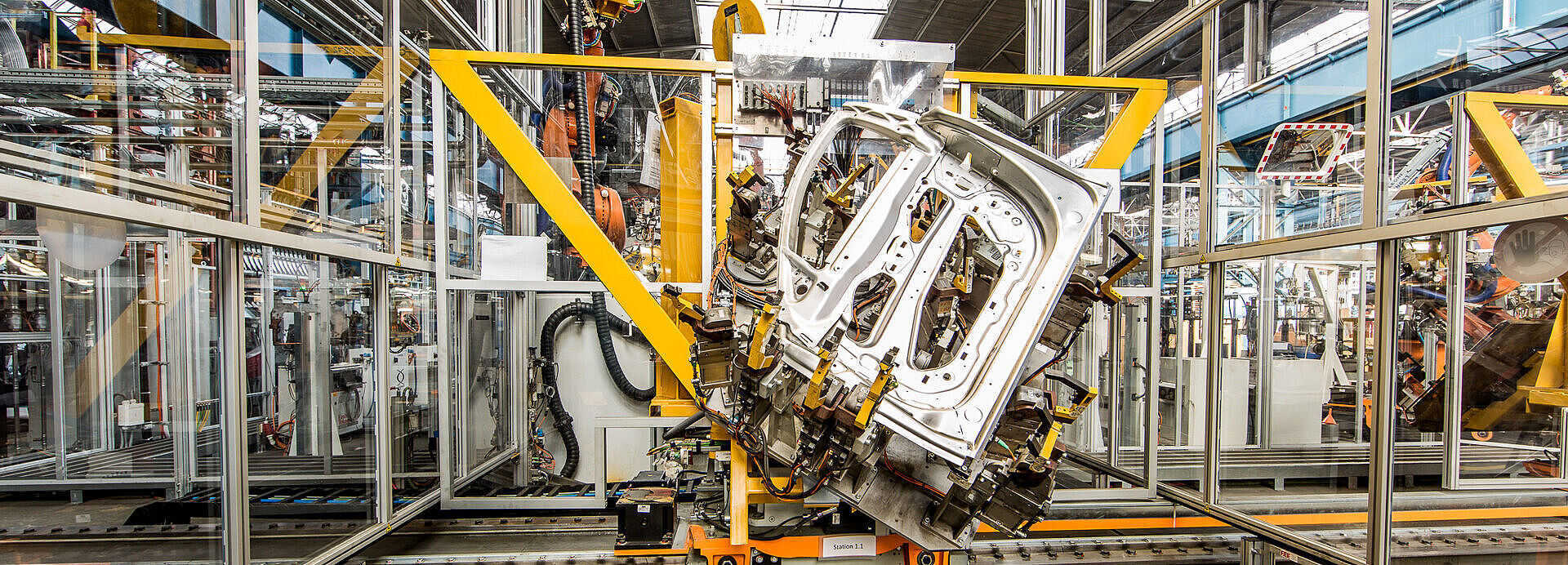

Our in-house relocation and integration team is able to integrate the most complex of parts into our existing universal cells. Depending on the age of the parts and the quantities involved, these can be produced by hand or with semi-automated or fully automated systems.